How can your innovation keep pace with the rapid change in today’s world?

PRECISION

IS WHAT WE DO

Aeroacoustics testing taken to a whole new level

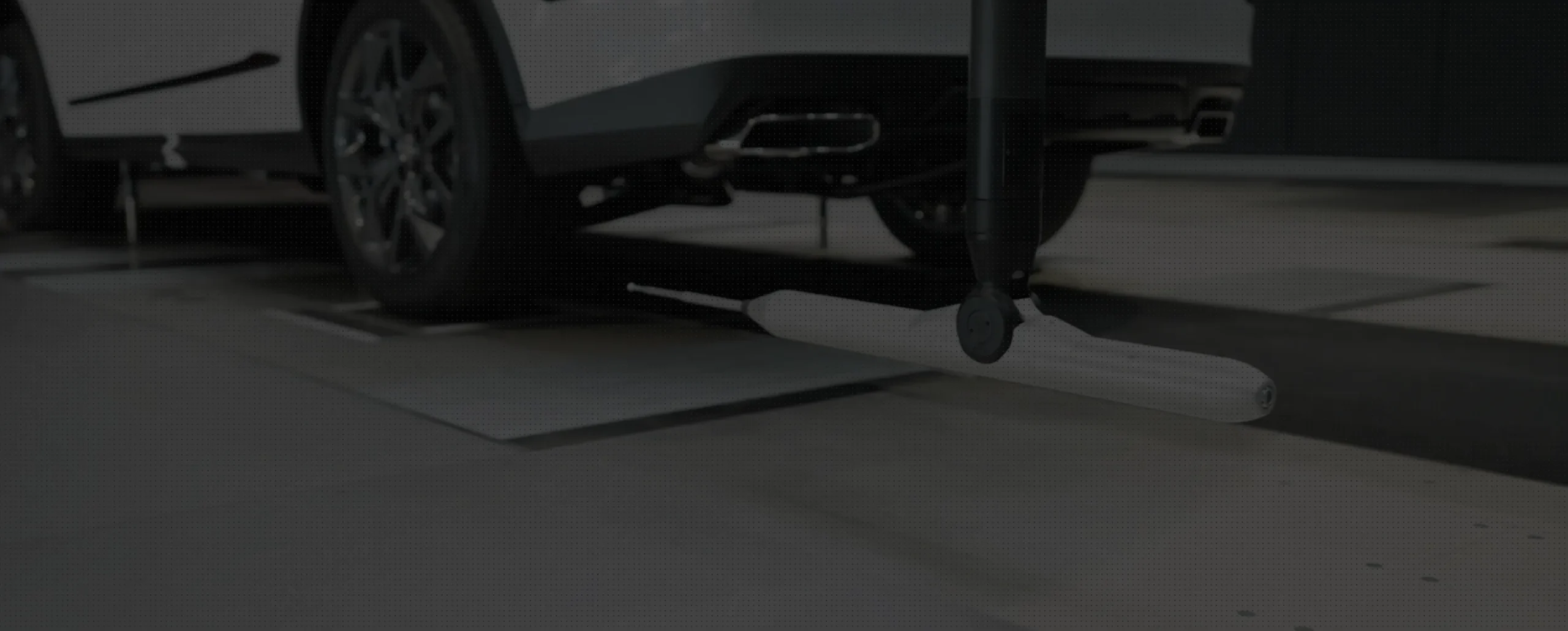

Aeroacoustics testing pairs wind with microphones to allow us to measure the noise that’s created.

Understand the impact of wind noise and make informed design decisions in one of the quietest tunnels in the world, with real-time data output visualization and access.

That’s how HALO’s aeroacoustics testing brings value.

A wind tunnel experience you won’t forget

Private office space and collaboration area

Private shop bay, kitchenette, and restroom

Integrated data system

State-of-the-art test area

Large work spaces

INNOVATION

STARTS HERE

Designed to be world-class in testing accuracy, efficiency, and human comfort.

Drag and tap to navigate facility

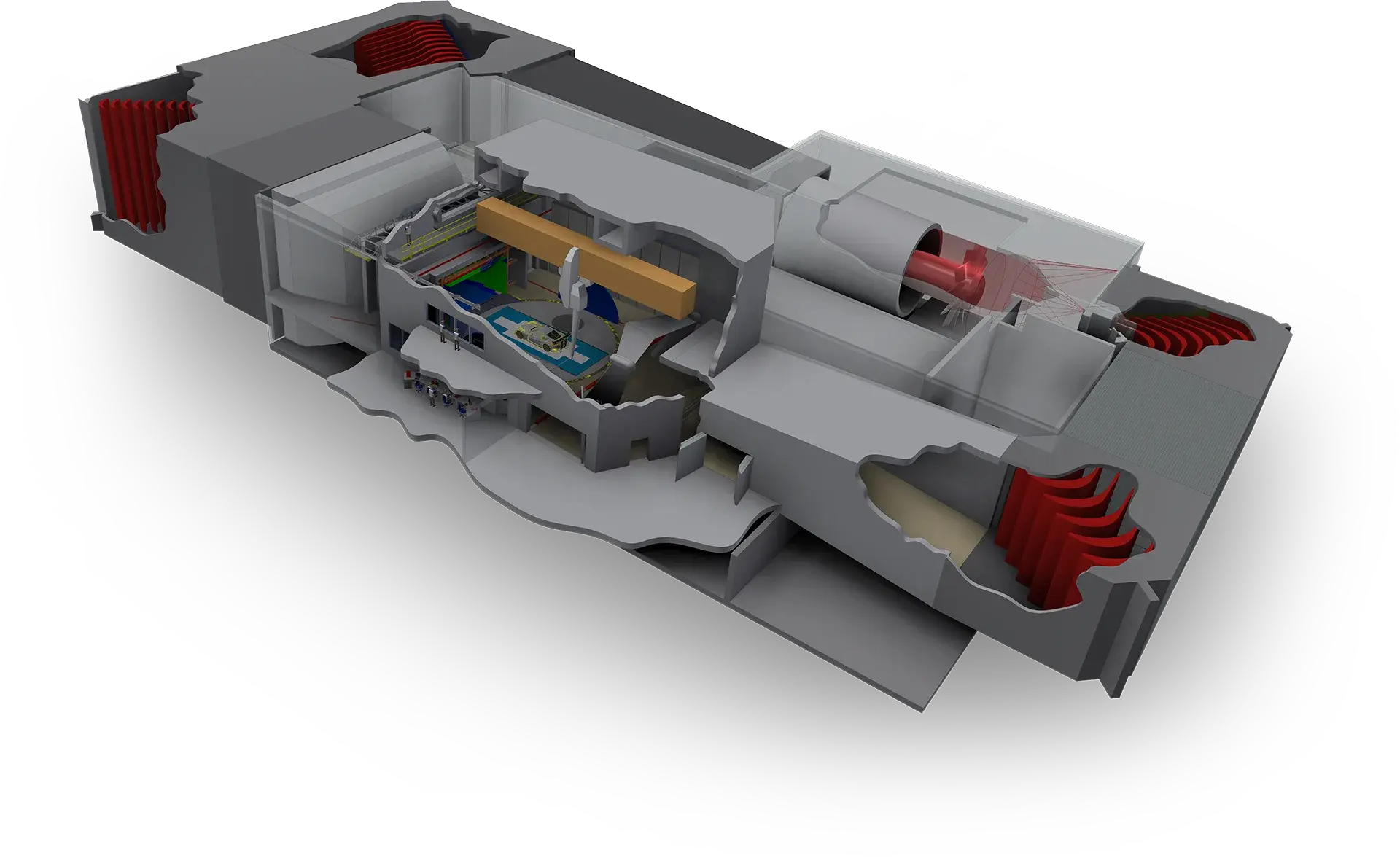

Control Room

- Spacious workspace to collaborate

- Windows and confidential outside area

- Kitchenette

Variable Nozzle

- 25 square meters = 250 kph (155 mph) wind speed

- 18 square meters = 310 kph (192 mph) wind speed

Heat Exchanger

- 10-50 degrees Celsius (50-122 degrees Fahrenheit)

- Maintains constant temperature

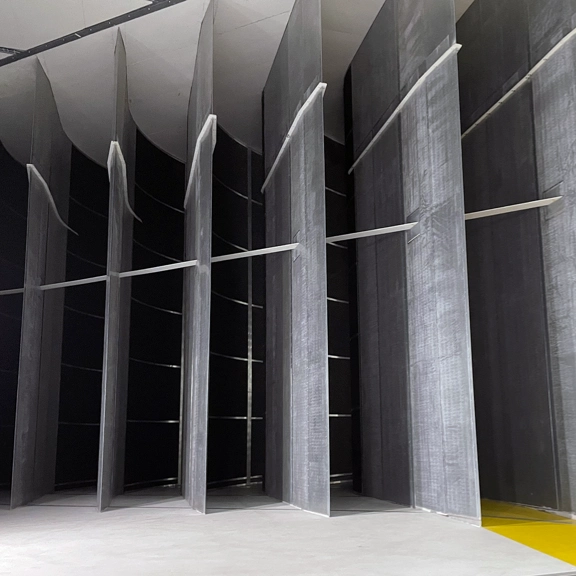

Settling Chamber

- Massive area behind the fan

- Allows airflow to settle before entering the test section

- Lowers turbulence level

- Allows quiet and uniform flow quality for good repeatability

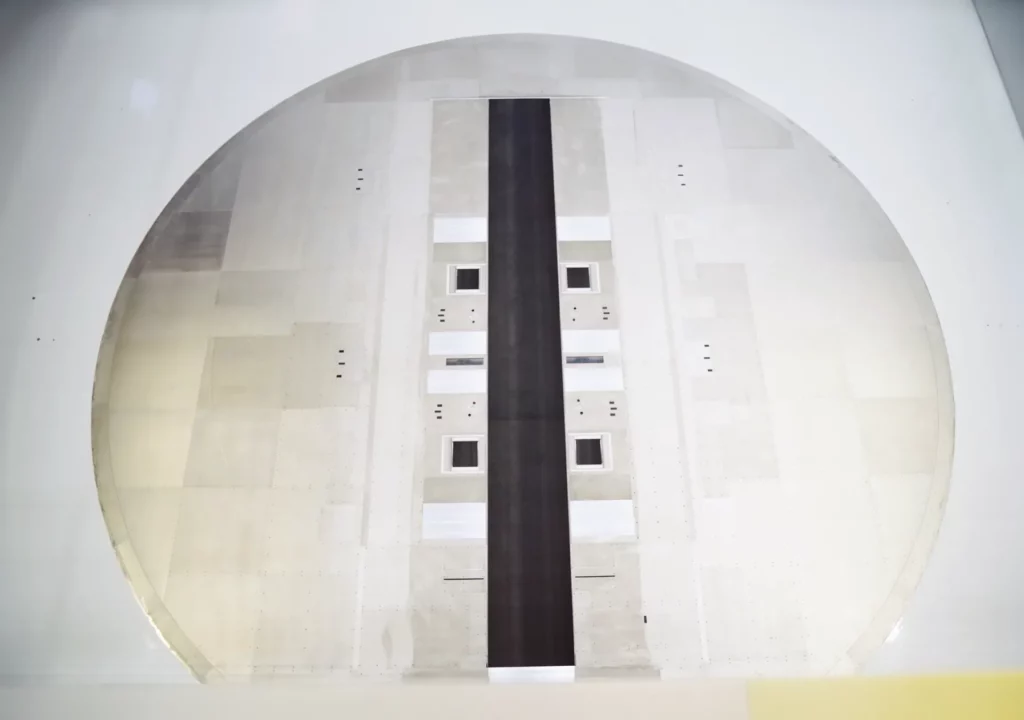

3/4 Open Test Section

- 3 meters x 5 meters x 15 meters

- Acoustic environment: <57 dBA @ 140 kph (87 mph) wind speed

- 12 meter diameter turntable with 180-degree rotation

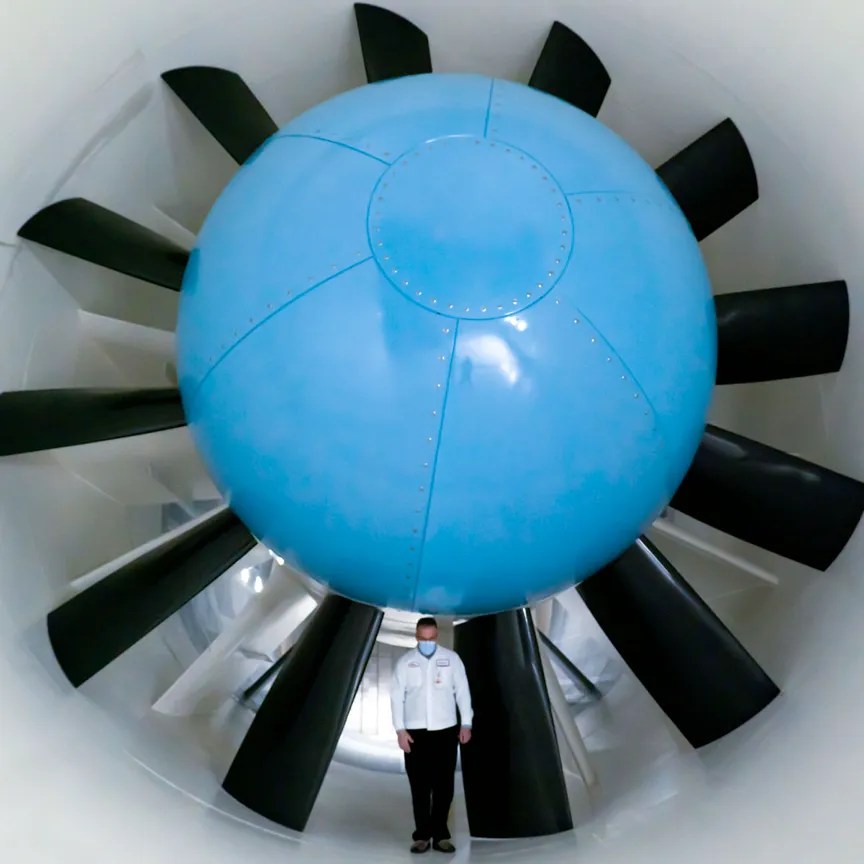

Fan

- 5 Megawatts (6700 HP)

- Diameter = 8 meters

- 12 Carbon Fiber Fixed-Pitch Blades

- Max rpm ≈ 250 @ 310 kph

- Inspection completed each day

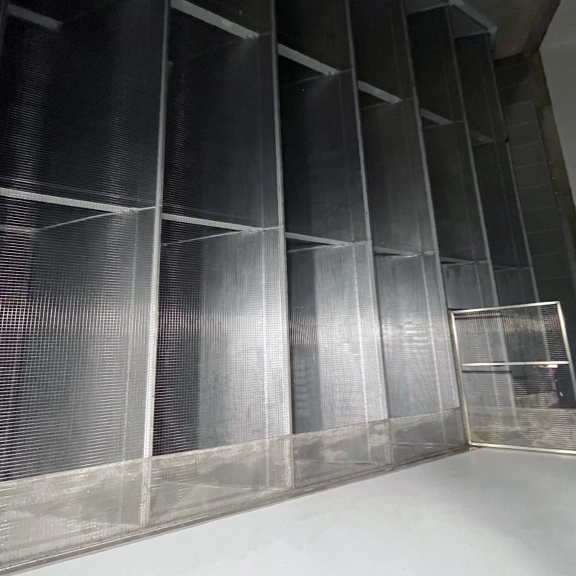

Turn 4

- Final turning vanes

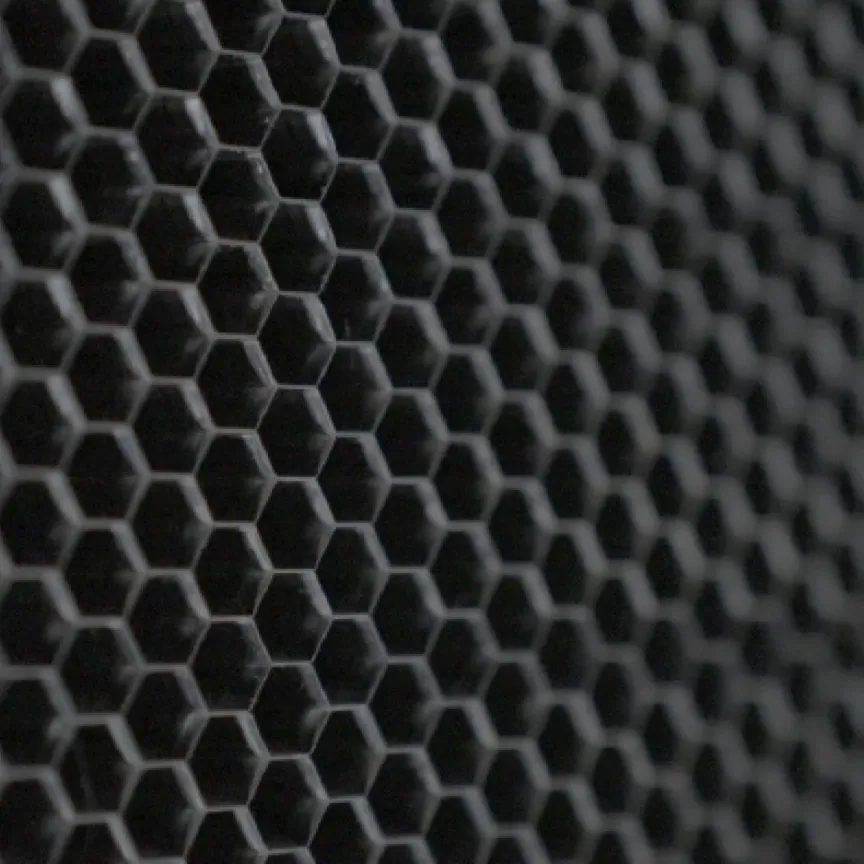

- Honeycomb screen to take out rotation in airflow

- Final screen equalizes flow and creates low turbulence level

Turn 2

- Before reaching the fan

- FOD (foreign object and debris) screen to protect the fan from any flying objects

Turn 1

- Turning vanes covered in acoustic panels

- Expand the airflow quickly to prevent flow separation

We’re here to take your wind tunnel experience to the next level.