RESEARCH

BRIDGING THE GAP WITH RESEARCH

Continuously exploring the intricacies of air

We all have something in common: We’re trying to understand the intricacies of air better, how it makes noise, how it creates forces, how it behaves.

Are you interested in being part of finding the solutions and testing the hypotheses?

Research is the core of how we can move forward so that we can advance society and make life better on our planet for everyone.

Our goal with research partnerships is to more deeply understand how air behaves and reacts regardless of the industry and product.

That’s why we have a significant research infrastructure in place with a number of academic and industry partners.

We’re continually investigating how aerodynamics and aeroacoustics can impact different industries with our wind tunnel’s unique capabilities, including evolving data acquisition methods and insights.

Leading the Research Efforts

Learn more about the Mobility Innovation eXchange in Aero/Acoustics (MIXA) symposium series.

Dr. Kevin Disotell

MIXA Managing Director

Coordinates industry education and research seminar series, the Mobility Innovation eXchange in Aero/Acoustics (MIXA).

Over 15 years of experience in wind tunnel test programs connecting university, industry, and government research partners

Tom Ramsay

RESEARCH AND TECHNICAL LEAD

Responsible for wind tunnel research endeavors

Tom’s quest is to make sure the wind tunnel gets the expected data and results as it relates to quality and repeatability of the intricacies of wind.

Over 30 years of experience in aerodynamic testing and simulation

Connect with MIXA Research

MIXA is led by Dr. Kevin Disotell at The Ohio State University Aerospace Research Center.

We want to hear from you!

For information about reserving time in the HALO wind tunnel for proprietary research, please contact us.

Research Updates

We are passionate about ongoing discovery about wind – not only acoustic or force-related, but also within our facility. We want to share what we’ve learned.

2023

01.10.23

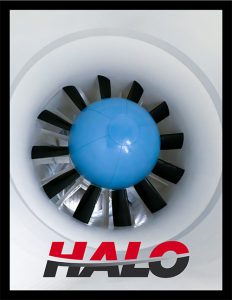

The Honda Automotive Laboratories of Ohio Wind Tunnel

The Honda Automotive Laboratories of Ohio (HALO) includes a new aeroacoustic wind tunnel located near Marysville, Ohio that started operations in 2022. This facility provides world-class aerodynamic flow quality and acoustic testing capabilities for the development of both passenger and motorsports vehicles.

Frequently Asked Questions

What kinds of testing can be done in the HALO wind tunnel?

While the HALO wind tunnel is capable of aerodynamic, aeroacoustic, and racing testing, the facility is only open to external users for aeroacoustic testing or testing involving wind-only needs.

What’s the range of wind speed for testing?

The wind tunnel can achieve a speed range up to 310 kph (192 mph).

What temperature range is the HALO wind tunnel capable of?

Thanks to the heat exchanger, the HALO wind tunnel can test from 10-50⁰ Celsius (50-122⁰ Fahrenheit).

How quiet is the test section when the wind tunnel is running?

<57dBA at 87 mph, as outlined in the diagram of the circuit

What type of system is used to measure aeroacoustics?

There are a series of microphone arrays—top, front, sides, and interior—made up of 502 external microphones and cameras and 54 internal microphones for use for sound source detection. Aachen heads are also utilized for interior vehicle acoustic analysis. This aeroacoustic array system has an external noise source accuracy of 5.0 cm.

How long does it take to move between tests?

The HALO wind tunnel is incredibly efficient when progressing from one test to the next. Two key components that make this possible.

- First, the test plan is preloaded into the control system. After the desired wind speed is reached, the data acquisition system starts gathering data. When data collection is complete, the control system advances to the next test step.

- Secondly, the speed at which conditions stabilize—allowing repeatable data to be gathered—is 20 seconds.

What other design features create a unique testing advantage for the HALO wind tunnel?

Turntable: The 12-meter turntable, where the item to be tested is secured, can rotate 180⁰.

Access: There are two doorways to the test section, allowing for efficient loading and unloading.

Spacious: The control room was designed with adequate space for your entire team.

How long does it take to install and remove a vehicle in the test section?

We can load a vehicle into the test section in less than 30 minutes.

What working space will I have at the HALO wind tunnel?

Each customer will have secure badge-controlled access to a shop bay with tools, a surface plate, work benches, a kitchenette, restroom, and a private office area with conference room.

When your testing session begins, not only is the control room large enough for your entire team, and it also provides a dedicated break area, private meeting room, and work bench for any minor part modifications.

Our badge reader system allows zone control so that all wind tunnel users maintain strict confidentiality.

How will I receive my data?

As testing progresses, your data will continually be written to a removable, passcode-protected hard drive that you will take with you upon completion of your testing.

When can I expect to get my results?

Results are viewable in real-time as testing progresses. You can do any additional post-processing and analysis utilizing the raw files on the secure hard drive provided.

Is photography permitted during testing?

Yes. To support confidentiality in the facility, a digital camera with a new memory card will be provided for your use during your test session. The memory card is yours to take with you upon completion of your testing.

We also have video cameras in the test section, and any video footage recorded during your testing time can be downloaded for your use.

You are permitted to take pictures in your bay area, office areas, and in the test section during your test.

What type of support will I receive during my test session at HALO?

Leading up to your test, a program manager will be your main point of contact. While onsite, you will primarily be working with a tunnel operator, test technician, and acoustic engineer (as needed).

Who is allowed to access the customer bay besides the customer?

Only the customer team and the third-party contractors who will be supporting your test. The badge reader system we use allows zone control and ensures strict confidentiality.

Do my team members need to complete any technical training prior to HALO wind tunnel testing?

We’ll work with you about what setting, filters, and other needs you have for your tests. We will have an engineer onsite during testing to support post-processing. If you would like to do additional data analysis after leaving the HALO wind tunnel, we can provide contacts for the appropriate licensing.

How long is a test day?

Your test session will run 7:00 a.m. – 4:30 p.m., continuously. Testing is available on Saturday and Sunday.

What food is available? Are meals provided during testing?

Due to the continuous testing cycle, we provide lunch and a full assortment of snacks and beverages throughout your test session. We do not stop testing for breaks, unless you opt to have a break.

What hours am I able to be onsite in my customer areas?

Our testing hours are 7:00 a.m. – 4:30 p.m. daily. Site access is available 6:30 a.m. – 5:00 p.m.

How do I reserve time at the HALO wind tunnel?

Contact Tim Savage or visit Goken’s website.

What kind of research do you do within the HALO wind tunnel?

We partner with The Ohio State University for non-proprietary, publishable research. Learn more at the MIXA page.

For information about reserving time in the HALO wind tunnel for proprietary research, please contact Tim Savage or visit Goken’s website.

Who oversees the research programs?

Due to the collaborative effort between industry and academia, the research program is overseen by The Ohio State University and HALO.

Where can I learn more and become involved?

• Learn more at the OSU MIXA page.

• Sign up to be on invite list for the next meeting.

We’re here to take your wind tunnel experience to the next level.